Having trouble making sand?

-

Unable to obtain the desired product yield and unable to make fine adjustments to improve it

-

An excessive amount of dust (waste loss) are generated

-

The shape of the finished product is not good

-

Not profitable due to excessive wear and high operational costs

-

The machine is too big and difficult to install

-

The machine requires high maintenance

Thfeatures in sand making.

The plant engineers who implemented

the system evaluated it as follows.

The Sand Refiner is more than just a hammer mill.

It is a "sand making machine" created solely to make sand.

In pursuit of reproducing the process of natural sand making,

a rational and simple sand making process with no waste has become possible.

Rresulting in an overwhelmingly high product yield with a minimum capital investment.

It is no longer necessary to consider inefficient equipment that

diverts machinery developed for other uses than sand making,

and somehow obtains sand size as a byproduct in a complicated process.

Sand Refiner maximizes sales with minimal investment in manufacturing sand-size products.

The Sand Refiner is more than just a hammer mill.

It is a "sand making machine" created

solely to make sand.

In pursuit of reproducing the process of natural sand making, a rational and simple sand making process with no waste has become possible.

Rresulting in an overwhelmingly

high product yield with a minimum

capital investment.

It is no longer necessary to consider inefficient equipment that diverts machinery developed for

other uses than sand making,

and somehow obtains sand size as a

byproduct in a complicated process.

Sand Refiner maximizes sales with minimal investment in manufacturing sand-size products.

Features

-

FEATURES 01

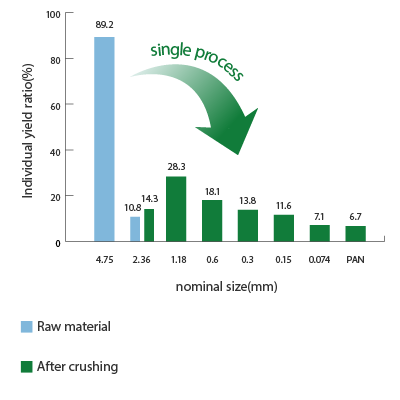

FEATURES 01Unrivaled production efficiency

Almost all of the loaded material can be converted to sand size (-5mm particles) in a single pass. This overwhelming production efficiency not only maximizes sales but also simplifies the plant configuration, thereby minimizing capital investment costs.

-

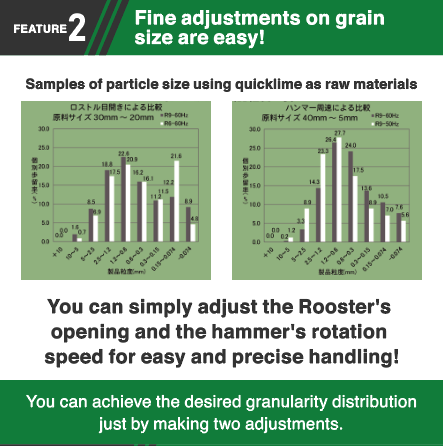

FEATURES 02

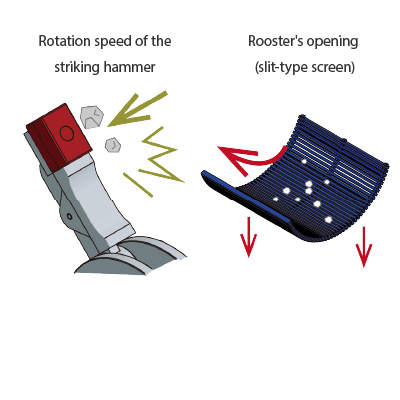

FEATURES 02Can easily make fine adjustments to the particle size

The particle size of the product can be adjusted easily by simply changing the rotation speed of the hammer and the Rooster's opening (slit-type screen).

-

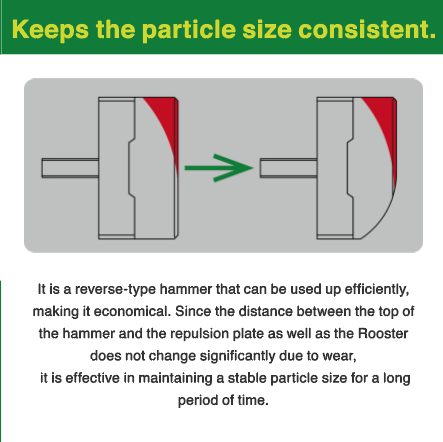

FEATURES 03

FEATURES 03Minimal generation of filler dust Friendly to the environment and to your wallet

The amount of dust (-0.074 mm particles) generated is about 10% of the raw material. A compact dust collector alone is sufficient for dust control. This helps minimize the loss in the production of sand products like crushed sand and foundry sand, where the amount of dust must be kept to a minimum,

-

FEATURES 04

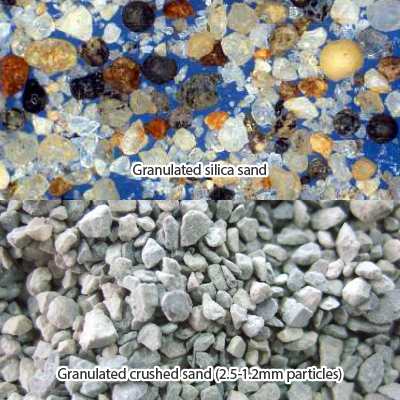

FEATURES 04Remarkable grain shape

It simultaneously crushes and refines the product, resulting in a fine, rounded grains shape.

-

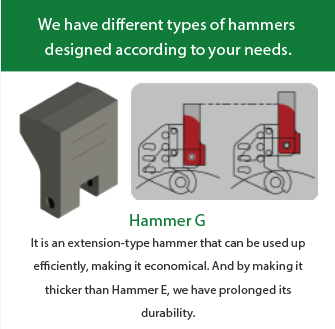

FEATURES 05

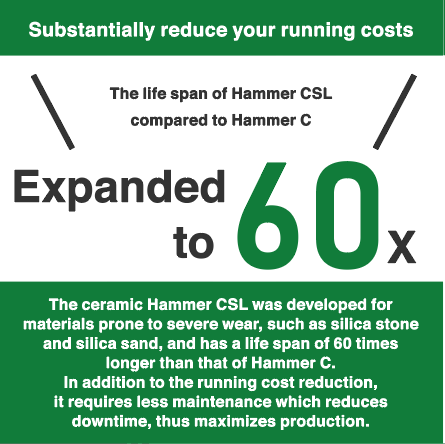

FEATURES 05Excellent wear resistance

The major consumable parts are made of special wear-resistant materials designed to prolong their lifespan.

-

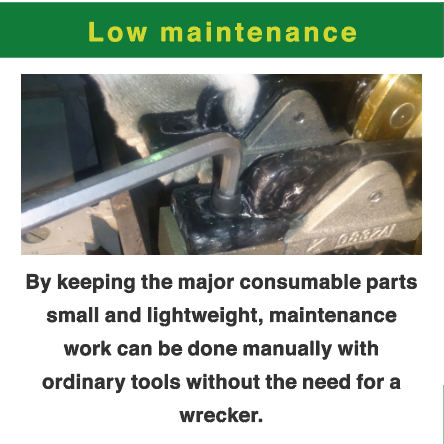

FEATURES 06

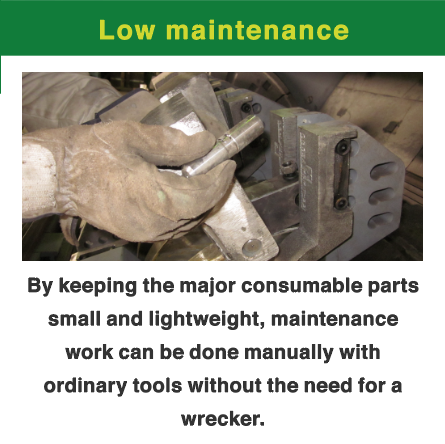

FEATURES 06Low maintenance

Since consumable parts have been made smaller and lighter, maintenance can be done easily by manually using ordinary tools. There is no need to use expensive heavy equipment such as a wrecker, thus reducing maintenance cost, minimizing downtime, and reducing the risk of accidents.

-

FEATURES 07

FEATURES 07Can be installed even in cramped spaces

Its compact size allows it to be installed in even the most intricate locations. Because of its overwhelming production efficiency with a minimum amount of dust generated, preparing separate bulky ancillary equipment is no longer needed, thus made it possible for space-saving installation.

-

FEATURES 08

FEATURES 08Low vibration and low noise

The NSR and EXR series have a no-load noise level of about 80 dB (at 1 meter and about 75 dB at 5 meters), while the MR-K500 series has a no-load noise level of about 75 dB (at 1 meter and about 65 dB at 5 meters).

CASE

Largest market share in Japan.

Sand Refiner is a dry-type sand making machine that was developed more than half a century ago. It has been a long-time seller, and is still in production with only minor model changes.

We are proud of the fact that this is the result of our devotion to the pursuit of the niche technology of sand making, and that we have accurately mastered the truth and essence of sand making.

No other sand making company in the world has been involved in the same industry for more than half a century, and no other sand making machine has the same structure as the Sand Refiner. The fact that we are a long-established sand making machine manufacturer and continues to be a top runner is the best evidence of our reputation.

In addition, the Nihon Keizai Shimbun and Nikkei Business Magazine have introduced our company for having the largest market share in Japan in terms of manufacturing and sales of dry-type artificial sand production equipment.

VOICE The plant engineer who implemented the system evaluated it as follows.

-

Upon seeing it, I was worried because it looked like an impact crusher and the structure was difficult to understand. But after testing it, it really crushes the raw materials to sand-sized pieces in just one pass. The product particle size was also remarkable.

I was concerned about the amount of dust (loss), but it only generated a handful, and the particles were round. Therefore, no ancillary equipment was needed in the post-processing. The plant could be made simple and compact.

Until now, there were only diverted crushers developed for purposes other than sand making, so they lacked the ability to make fine adjustments. However, Sand Refiner can easily perform fine adjustments. If you want to make sand, you should select a machine that was born to make sand.Onoda Cement Co., Ltd. Niimi Factory (former)

-

Each parts are light, so they are easy to replace. The consumables are cheaper than the impact crusher we used before, and the grain size is consistent.

Artificial Silica Sand Manufacturer

-

Low maintenance and easy to replace parts

Precious Metal Refining Company

-

Compared to the ones we have used before (pin mill and cage mill), it has a higher processing capacity and the grains after crushing are consistent.

Limestone Mine

-

Compared to other companies’ products, it has less vibration and is compact enough to fit in a small space.

Silica Sand Processing Company

-

Since the installation space was small, the sand refiner was the best option because it could produce the desired product in one pass and did not require any ancillary equipment.

Quicklime manufacturer

FAQ

-

What is the particle size range?

We specialize in the production of sand size particles of 5mm or less. When it comes to the production of neither a lump of gravel nor a powder, but any size in between, we are unrivaled.

-

How much humidity is allowed in the raw material?

It depends on the size of the raw material, but in general, it is less than 2%.

-

What is the replacement cycle for consumable parts?

Since it varies greatly depending on the raw material and grain size, we cannot give a general answer. However, we often receive positive comments from our customers saying, "We were able to dramatically reduce the running costs after switching to the Sand Refiner." Please feel free to contact us for details.

-

What is the delivery timeframe?

Please allow 8 to 14 weeks for delivery. If ancillary equipment is included, it may depend on the delivery date of the ancillary equipment.

-

What are some things we need to keep in mind when implementing the system?

The condition of the raw materials is important for the stable production of high-quality products. The key points are to avoid feeding wet raw materials, to remove metallic foreign substances from raw materials, and to supply raw materials in fixed quantities.

PRODUCT

-

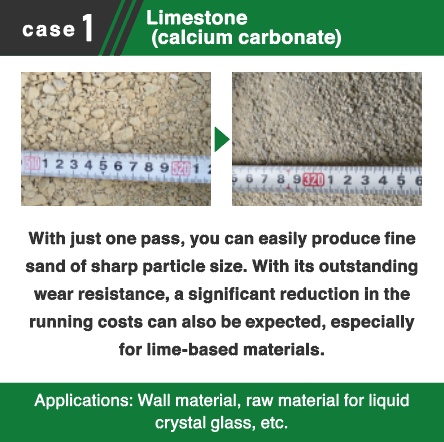

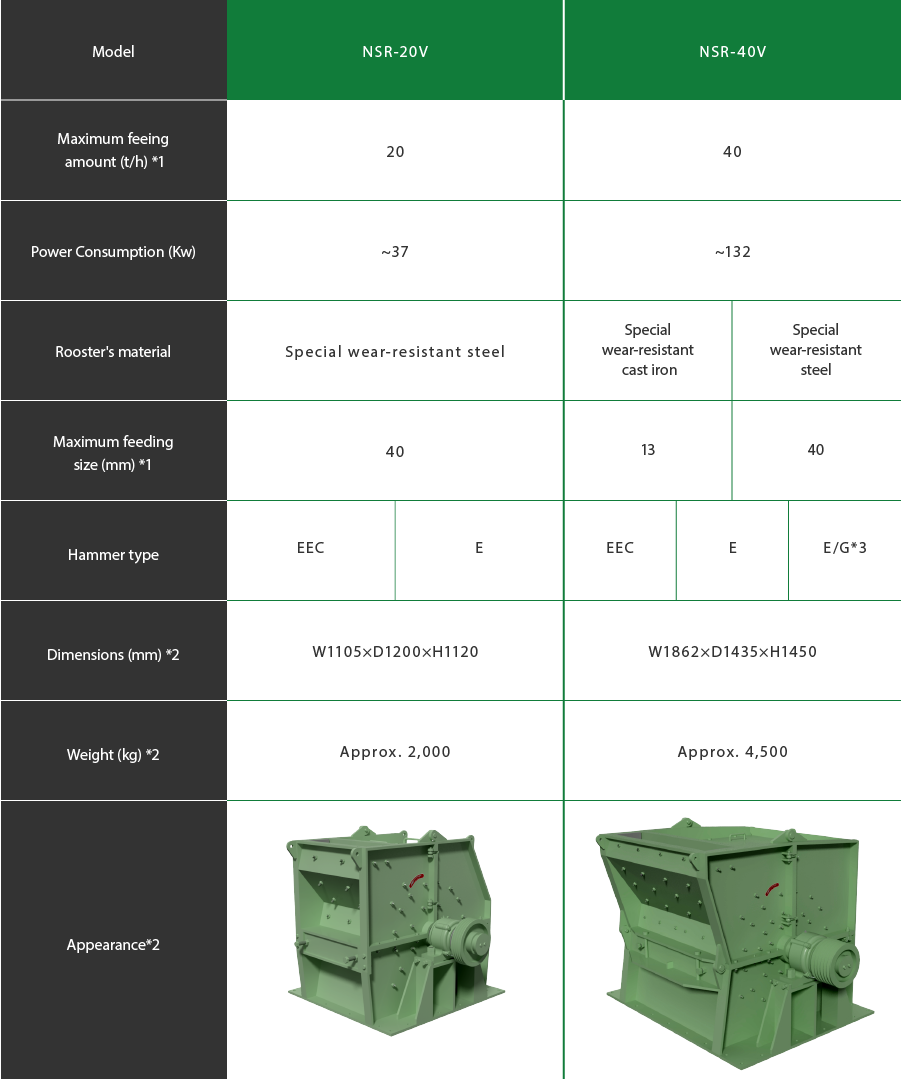

NSR Series

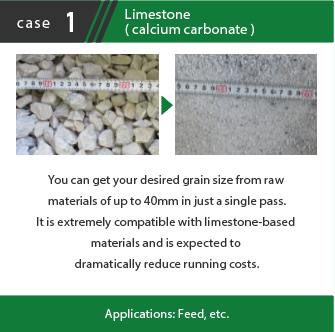

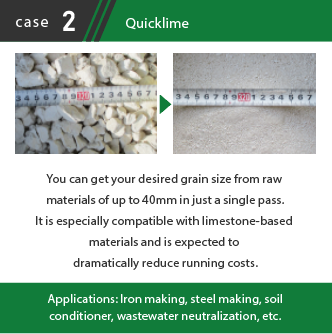

Crush 40mm raw materials into sand in an instant! We have a lot of experience, especially with limestone materials.

It is distinguished by its high crushing ratio, which can reduce 40mm raw materials to 5mm or less in an instant.

Since almost all of the input raw materials can be reduced to sand size products in a single pass, you can skip the rough grinding process and the return process of crushed products, making the plant more compact and saving on capital investment costs and electricity.

For more than half a century, our products have been well received especially in the field of sand making from lime-based raw materials such as calcium carbonate and quicklime ( feed, soil conditioner, water conditioner, iron and steel making, paint, glass, etc.).

*1 Varies depending on the quality of the raw material and the Rooster's opening.

*2 Specifications and appearance are subject to change without notice.

*3 Only special wear-resistant cast iron grating material can be used for Hammer G. -

-

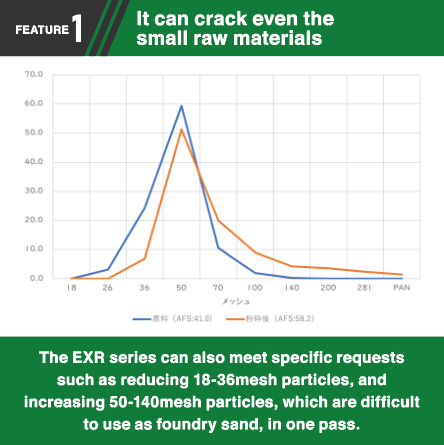

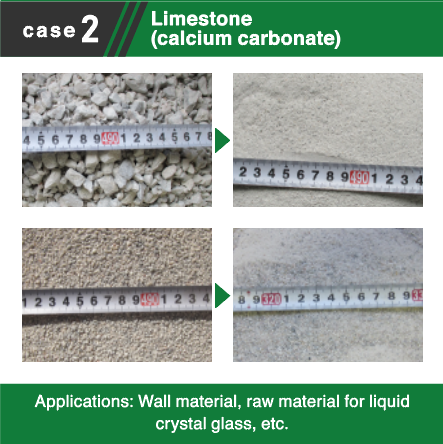

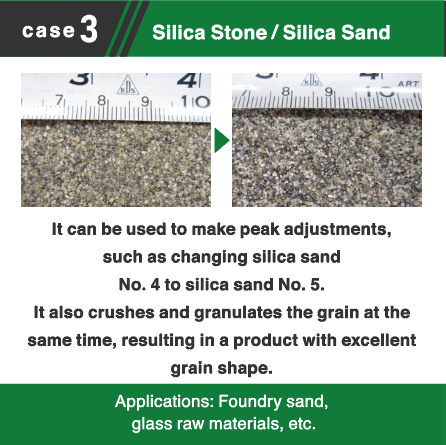

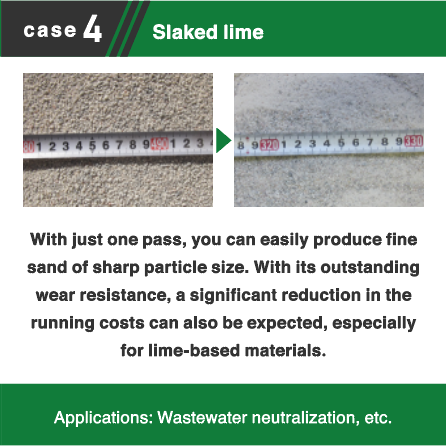

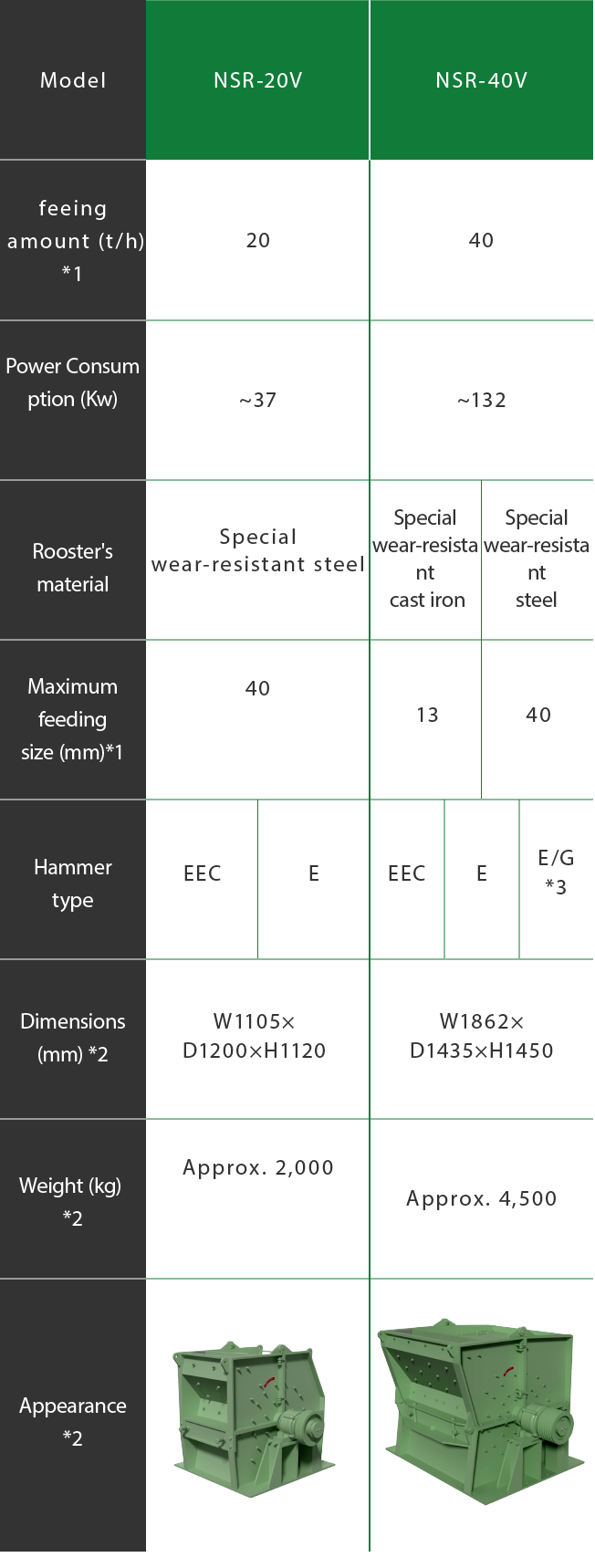

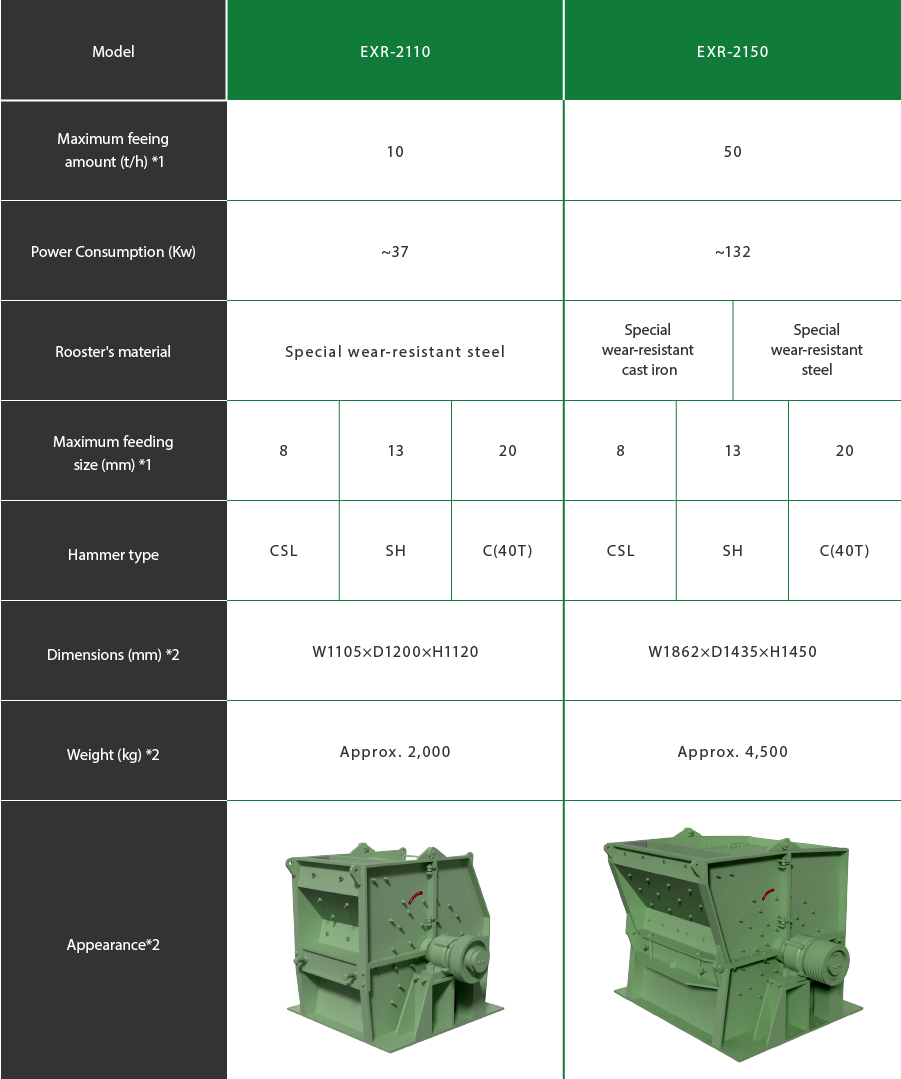

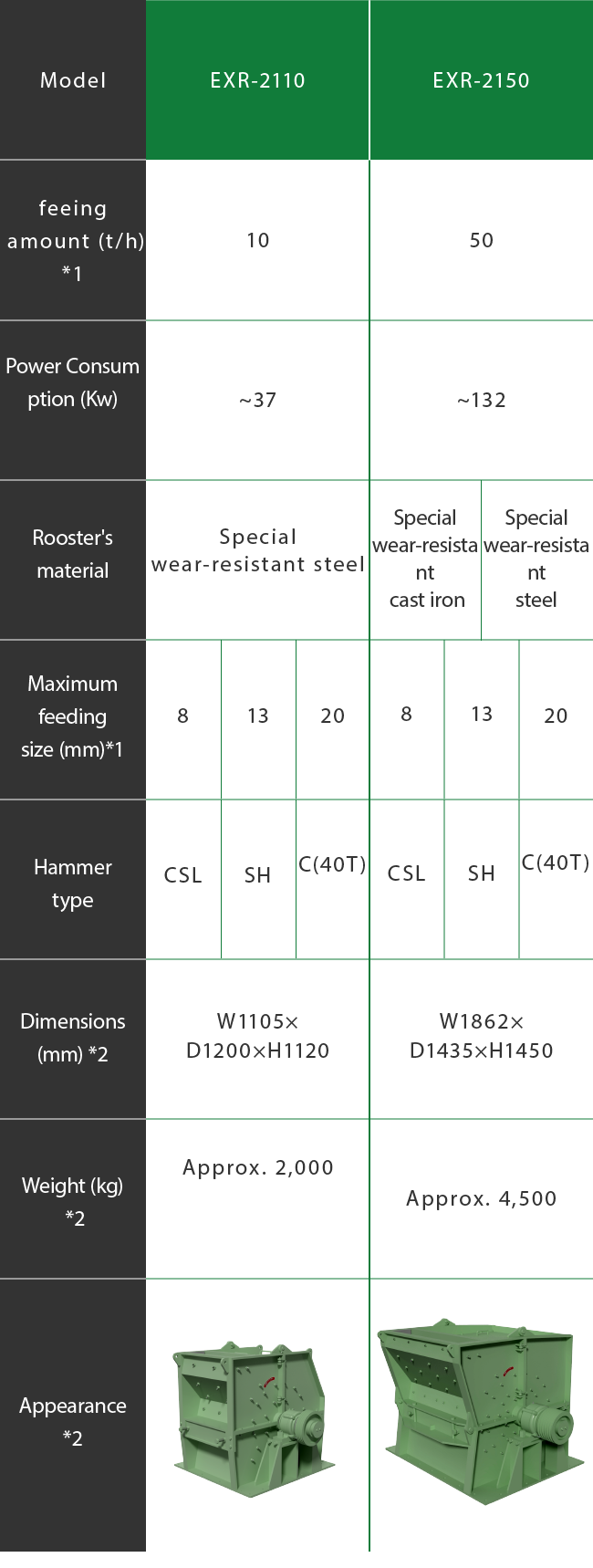

EXR Series

Suitable for sharp fine sand production such as silica sand with an overwhelming yield of 14 to 100mesh

Using pebbles of around 10 mm as raw material, this machine can make sharp fine sand to yield 14 to 100 mesh (1.4 to 0.15 mm), or make peak adjustments on the grain size that cannot be seen visually, like adjusting silica sand No. 5 to make silica sand No. 6.

In addition, the granulation effect occurs at the same time as crushing, producing an excellent grain shape.

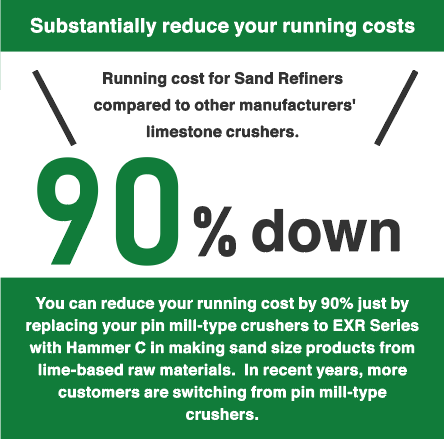

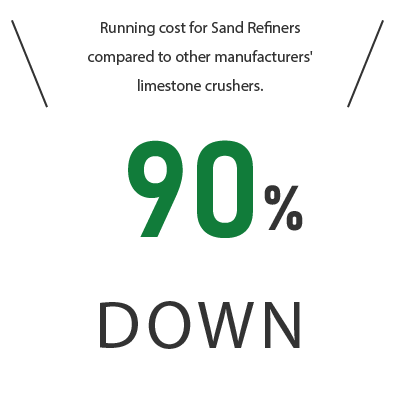

With the outstanding wear resistance cultivated in silica sand, we have achieved a 90% reduction in running costs by replacing pin mill and cage mill in sand production with limestone materials. We are still increasing the number of replacements.

Raw materials such as limestone (calcium carbonate), silica stone/silica sand, slaked lime, zeolite, and coke are used to make products such as wall materials, glass materials, foundry sand, wastewater neutralization, soil conditioners, desiccants, ethylene adsorbents, catalysts and antibacterials.

*1 Varies depending on the quality of the raw material and the Rooster's opening.

*2 Specifications and appearance are subject to change without notice. -

-

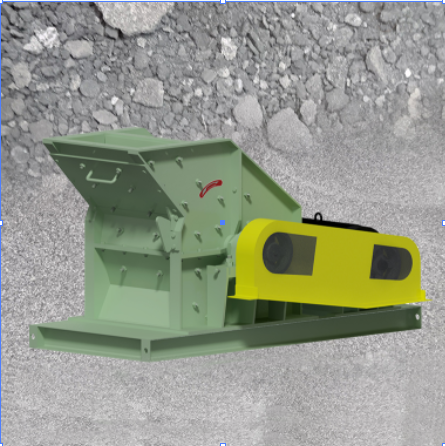

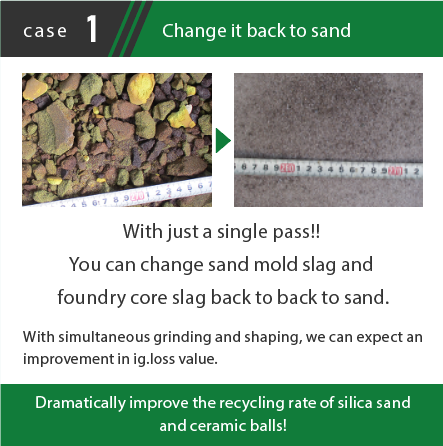

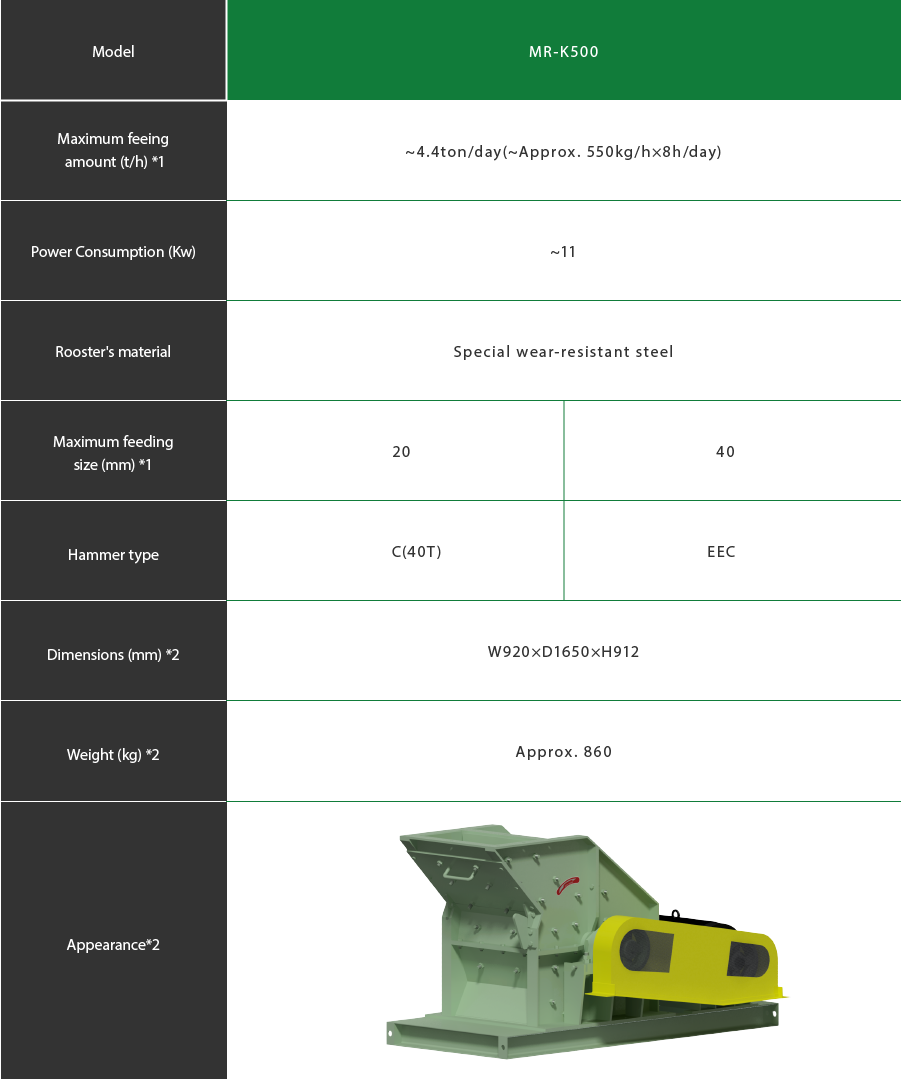

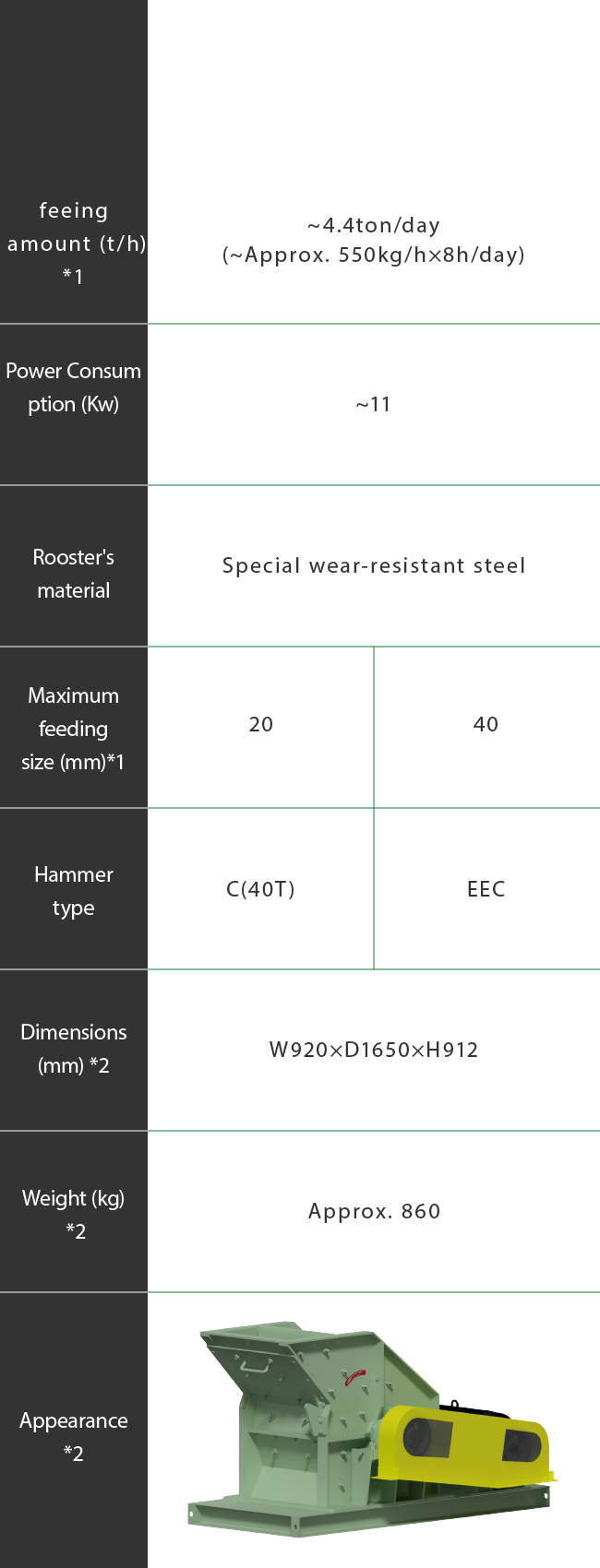

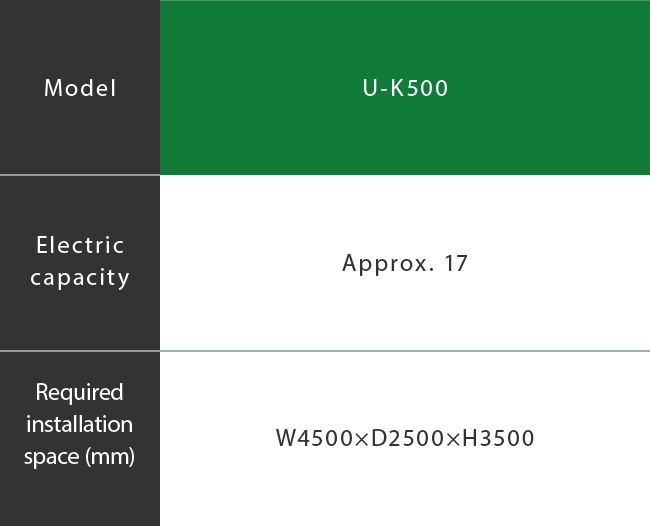

MR-K500 Series

Compact type, less than 5 tons/day For crushing of sand mold slag and foundry core slag

It is compact and easy to use while maintaining the advantages of the NSR and EXR series.

As a class with a processing capacity of less than 5 tons/day, it has excellent abrasion resistance and is mainly used for casting to reproduce silica sand and cerabeads (to change sand mold slag and foundry core slag back to their original state).

Other applications include precious metal recycling (slag grinding) and quicklime grinding (steel making).

*1 Varies depending on the quality of the raw material and the Rooster's opening.

*2 Specifications and appearance are subject to change without notice. -

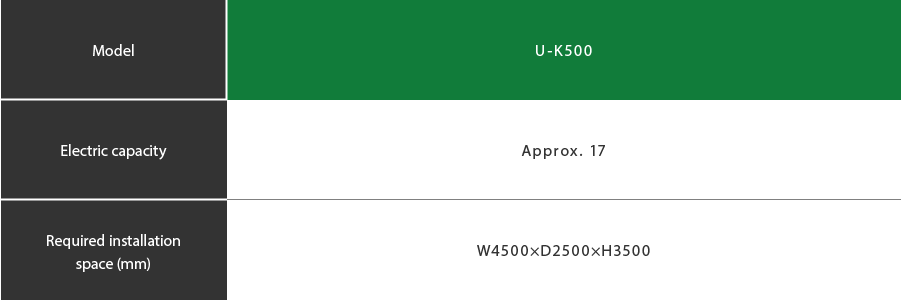

All-in-one unit types are also available.

The MR-K500 series is a compact and easy-to-install all-in-one unit with a material hopper, vibratory feeder, discharge conveyor, dust collector, and control panel.

FLOW

-

01

Consultation

We will ask you about the material (name, size, moisture content, etc.), desired crushing size, desired processing capacity, etc., and select the appropriate model and its feasibility.

-

02

Conducting a crushing test

We will conduct a crushing test to see if it meets your requirements. (You may attend).

-

03

Quotation

Based on the test results, we will select the appropriate model and specifications, then provide you with a quotation.

-

04

Placing an order

The contract will be made upon the receipt of the order form.

-

05

Production

We will manufacture the machine based on your order.

-

06

Delivery

We can also provide test run adjustments and operation explanations.

CONTACT

For queries regarding sand making machines, sand refiners,

media shredders, Mighty Security, etc., please contact us.

Office hours: 9:00-17:00

(except weekends and holidays)