Aren’t you forgetting something?

Important points to consider before

implementing a sand making facility

-

Will you make a profit from producing that crushed sand?

-

Will you make a profit with that equipment cost?

-

Will you make a profit with that running cost?

With SUN,

you can make profitable

crushed sand.

It is a given that crushers should be able to produce crushed sand with a quality that meets JIS standards.

The important thing is to be able to produce

1) crushed sand that can sell 2) in a stable manner, and 3) at a reasonable price.

With SUN, which is composed of its core,

Sand Refiner, a dry-type crusher that was born solely to produce sand,

and a unique classifier and dust collector that is directly connected to the Sand Refiner,

it is easy to make such ideal sand making into reality.

That’s how you profit

It is a given that crushers should be able to produce crushed sand with a quality that meets JIS standards.

The important thing is to

be able to produce

1) crushed sand that can sell

2) in a stable manner, and

3) at a reasonable price.

With SUN, which is composed of its core,

Sand Refiner, a “dry-type” crusher that

was born with the mission of producing

sand, and a unique classifier and dust

collector that is directly connected to

the Sand Refiner, it is easy to make such

ideal sand making into reality.

That’s how you profit.

Features

-

FEATURES 01

FEATURES 01JIS standard crushed sand in a one pass

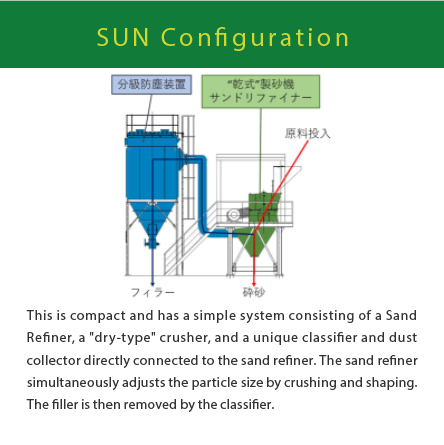

SUN is a compact crusher based on Sand Refiner, a dry-type sand making machine developed with the mission of producing sand. It simultaneously crushes and refines almost the entire load into products that meet JIS requirements in a just single pass, while efficiently filtering dust with its unique classifier and dust collector that are directly connected to the machine.

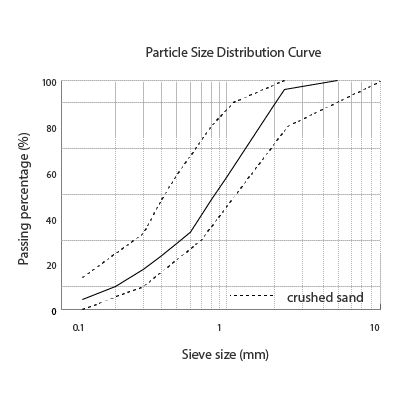

With SUN, you can produce crushed sand that meets the requirements of JIS standards in almost a single pass, using almost any raw stone. -

FEATURES 02

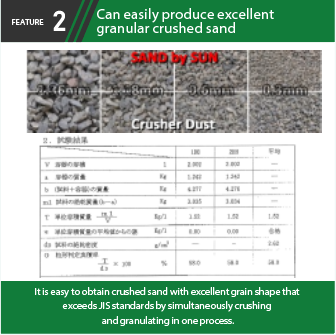

FEATURES 02With SUN, you can freely produce crushed sand that can sell.

It goes without saying that sand making facilities can produce crushed sand that conforms to JIS standards. However, to be able to sell it is a different matter. It is more important to satisfy the needs of the customers who will purchase and use the product, rather than whether or not it conforms with JIS standards. SUN can easily adjust the product particle size and fineness to meet the users' needs, from fine sand to coarse sand, and from single-type sand to blended-type sand.

-

FEATURES 03

FEATURES 03Stable production Wear resistant & easy maintenance

Sand Refiner, a dry-type sand making machine that was used as the core of SUN, uses special wear-resistant materials for its main consumable parts. The shape and the way they are installed have been devised to prevent changes in grain size due to wear. In addition, the parts are compact, lightweight, and can easily be replaced manually with ordinary tools, so when a change in particle size occurs due to wear, it can be dealt with immediately.

-

FEATURES 04

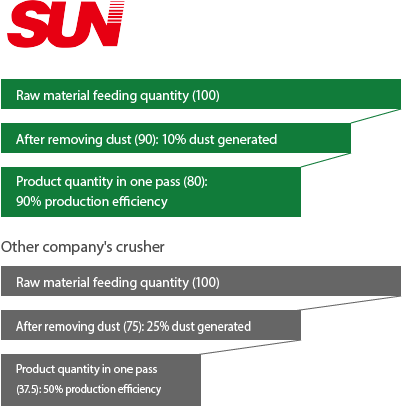

FEATURES 04Unparalleled production efficiency that maximizes sales

While many sand making facilities utilize machines that were not originally developed for the purpose of sand making and produce sand as a byproduct by repeatedly returning it in a complicated process, SUN specializes in the production of crushed sand and can produce sand in a simple and compact process in a single pass. This is where the overwhelming difference in production efficiency arises. Since it generates less dust, the waste loss is also kept to a minimum, allowing SUN to maximize sales.

-

FEATURES 05

FEATURES 05Turn you dead stock into money

SUN can produce crushed sand from your bad inventory of stone dust and coarse aggregate. In other words, you can make money out of what you cannot sell. This is because SUN can simultaneously process crushing and classification and can easily make fine adjustments.

-

FEATURES 06

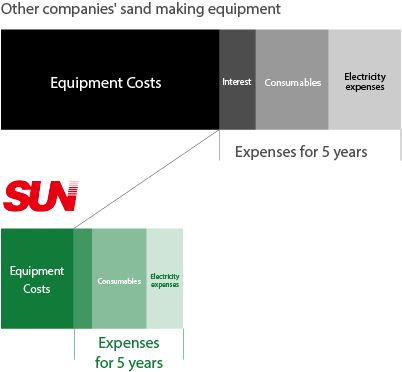

FEATURES 06Compact design that minimizes expenditures

Since SUN can process crushing, granulation, and classification simultaneously, there is no need to prepare a separate classifier, such as an air separator. In addition, since this is a dry-type, there is no need for a washer. As a result, it can be installed in a small space, requires less electricity, and above all, minimizes the initial investment cost. Running costs can also be reduced thanks to its excellent wear resistance, thus reducing the total expenditure.

CASE

We are currently expanding our distribution to overseas market

The depletion of natural sand has become an issue in the world, and crushed sand is attracting attention as an alternative material.

Although a number of foreign manufacturers are also manufacturing crushers, there’s no such equipment as SUN, which was developed solely for sand production. As a result, they produce inefficient and low-quality crushed sand.

To address this issue, SUN is being sought after around the world.

VOICE The plant engineer who implemented the system evaluated it as follows.

-

Each machine has its own birth (with its initial design purpose) and is born with its own role to play. Therefore, when selecting a machine, it is necessary to look at its origin. No matter how many crushers that were designed for other purposes are converted and modified to produce artificial sand because of the current boom, problems will occur because of their different origins. In this respect, SUN was born 35 years ago as a sand making device and has been modified for over a long period of time to this day. I think it is a perfected machine, and that is what makes it different from others.

-

To put it simply, the sand produced has an excellent shape.

-

I was surprised at how quickly they got the plant up and running.

-

The problem at hand is the excess amount of filler the machine produces. It is quite difficult to deal with. We should choose a machine that produces less filler. And yes, this machine produces much less filler

-

I’ve been told that the processing power of the sieve (for returning the oversize materials in the post-process) is not enough, but I’m doing it with ease. Why? Because the crushing efficiency is so great that there is hardly any oversize. Hmm, is this what you call crushing efficiency? Hmmm.

-

We can pretty much work with the product particle size requested by the customer. From coarse sand to fine sand, we can make anything that meets your needs.

FAQ

-

How do I adjust the product particle size?

You can easily adjust the particle size by following these steps.

(1) Change the Sand Refiner's Rooster opening.

(2) Adjust the hammer's rotation speed of the Sand Refiner.

(3) Adjust the airflow volume of the classifier and dust collector. -

What is the water content ratio of the raw material?

It depends on the size of the raw material, but as a rule, it is less than 2%.

-

Is it necessary to have a dust collection system?

No additional dust collector is needed for the Sand Refiner.

It has its own unique classifier and dust collector. As the name implies, it acts as a dust collector as well as a product classifier. -

How much is the running cost?

It varies greatly depending on the raw material, but the running cost per ton of finished product* is about 80-350 yen (in our experience, the average is about 120 yen). The electricity cost is about 60 yen per ton of finished product.

*Other companies may use the cost per ton of the raw material input, but then, the production cost fluctuates depending on the production efficiency, making it difficult to see the facts. So, we use the cost per ton of finished product, which is easier to understand. This is because we are confident in our overwhelming production efficiency. -

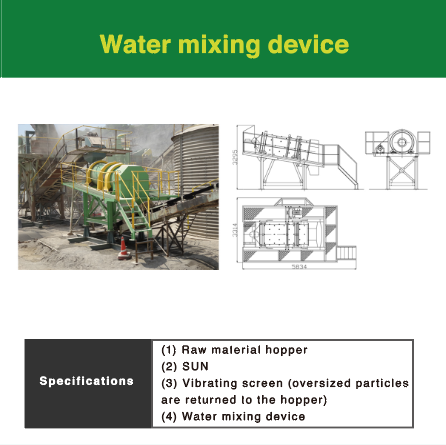

Isn't it difficult to handle dry crushed sand?

The crushed sand produced by SUN can be processed into a water mixing device in the final process to make wet sand. This is made possible only because SUN produces less dust filler.

-

What is the delivery timeframe?

About four months.

-

What are some things to keep in mind when implementing the system?

The condition of the raw materials is important for the stable production of high-quality crushed sand. The key points are to avoid feeding wet raw materials, to remove metallic foreign substances from the raw materials, and to feed raw materials in fixed quantities.

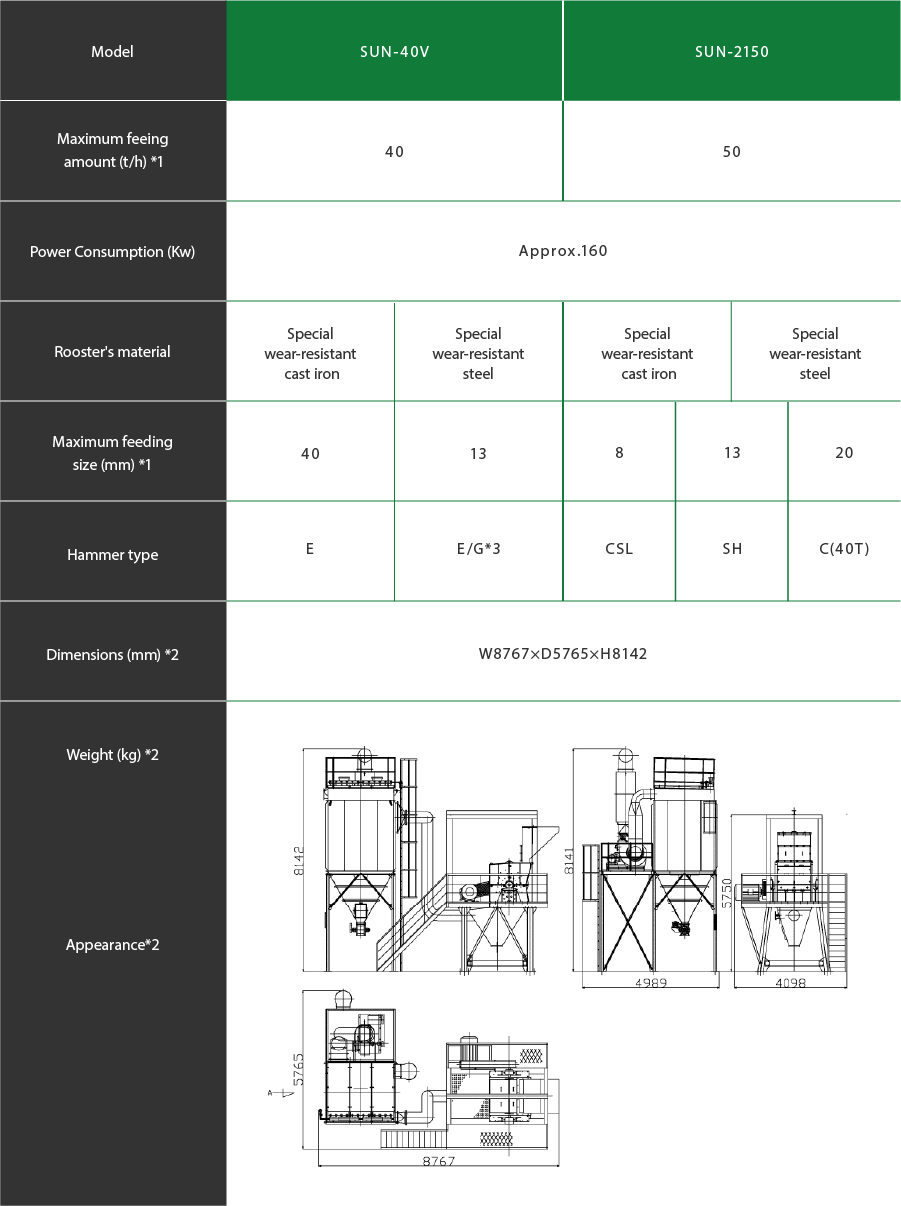

PRODUCT

-

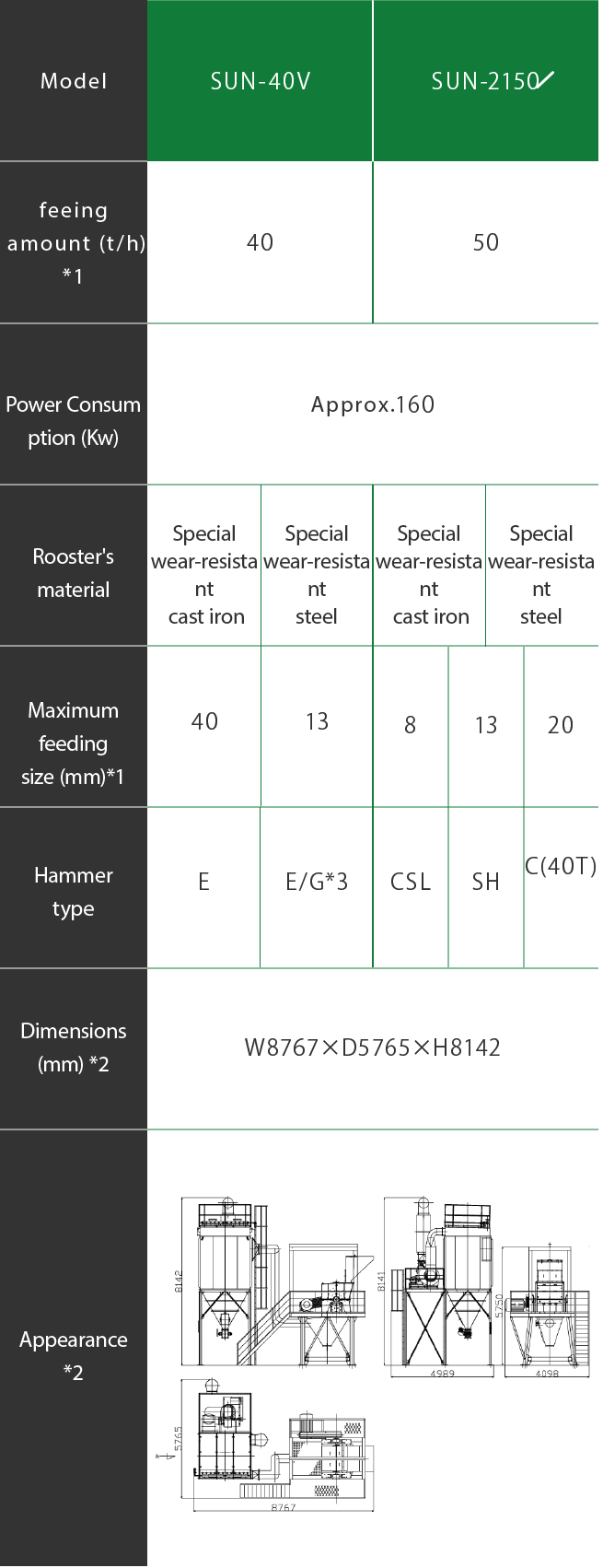

SUN Dry-type sand manufacturing unit

This is all you need for crushed sand production.

Your all-in-one sand making unit.SUN is composed of its core, Sand Refiner, a dry-type crusher that was born with the mission of producing sand, and a unique classifier and dust collector that is directly connected to the crusher. It can process crushing, granulation, and classification simultaneously.

Why don’t you start a profitable sand making business with SUN?

*1 Varies depending on the quality of the raw material and the Rooster's opening.

*2 Specifications and appearance are subject to change without notice.

*3 Only special wear-resistant cast iron grating material can be used for Hammer G. -

-

-

-

-

-

-

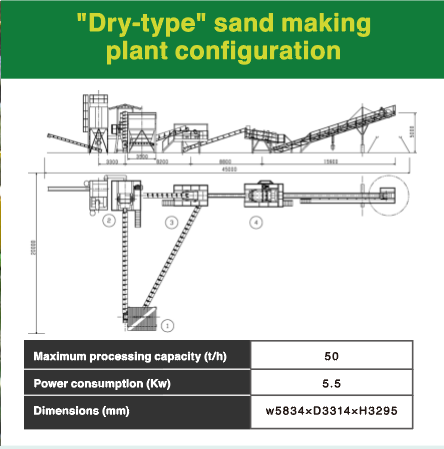

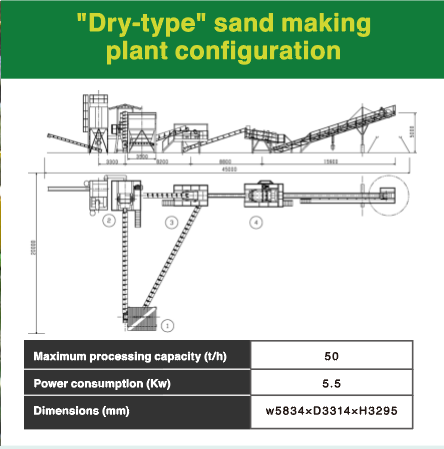

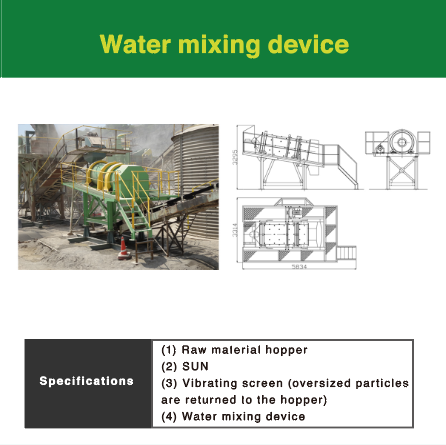

Dry-type sand making plant (reference example)

In general, we recommend running the sand through a water mixing device at the end of the sand making process. By blending the water into the sand, the particle size can be kept even during storage, and the quality of the product can be managed easily and stably. In addition, it has the advantage of making moisture management easier for sand purchasers.

The ability to add water in the final process is due to the low filler content.

FLOW

-

01

Consultation

We will ask you about the material (name, size, moisture content, etc.), desired crushing size, desired processing capacity, etc., and select the appropriate model and its feasibility.

-

02

Conducting a crushing test

We will conduct a crushing test to see if it meets your requirements. (You may attend).

-

03

Site inspection

We will inspect the site of the proposed installation and discuss the layout.

-

04

Quotation

Based on the test results, we will select the appropriate model and specifications, then provide you with a quotation with a layout plan based on the site inspection.

-

05

Placing an order

The contract will be made upon the receipt of the order form.

-

06

Production

We will manufacture the machine based on your order.

-

07

Delivery

We can also provide test run adjustments and operation explanations.

CONTACT

For queries regarding sand making machines, sand refiners,

media shredders, Mighty Security, etc., please contact us.

Office hours: 9:00-17:00

(except weekends and holidays)